CASCADIA iM-225

TTI TORQUEBOX®

For more motors the TorqueBox® fits, see our Catalog

EV TORQUEBOX® SUB-ASSEMBLIES

"TorqueBox® Sub-Assemblies from Torque Trends Inc.:

The Future of Electric Vehicle Gearbox Manufacturing"

Benefit: With an eight inch diameter the planetary based TorqueBox® in 1.58, 1.90 and 3.00 to 1 ratios fits into tight places and most automotive transmission tunnels. The TorqueBox® is also 1/3 to 1/2 of the transmission weight it is replacing, reducing overall weight is good for range and makes installation easy.

Benefit: The input shaft is designed (material and design) to allow up to 15 degrees of flex, both directions of rotation, without damage, this reduces the chance of fracture due to high spike torque loads. This means you can place our HD TorqueBox® behind up to 1250 lb ft of torque without concern.

Benefit: We use only high quality bearings and micro-shot-penned EN-36 gears to assure continued high rpm (up to 20,000rpm) use in our 3.00 to1, our 1.58 and 1.90 ratio have bearing and gear upgrades for motors above 10,000rpm.

Benefit: We use only 100% full synthetic ATF fluid and directed splash lubrication in all planetary based TorqueBox® units. This allows both high and low temperature lubrication and something called misting, which is crucial for full rotating mass lubrication. Our Torque Vectoring Dual Motor TorqueBox® use full synthetic 75W90 gear oil.

ev - TORQUEBOX®

EV Reduction Gearbox by Torque Trends Inc.

What you need to know (For all your EV Applications)

Conventional transmissions, manual or automatic are designed for internal combustion engines. The multiple gear ratios and ratio spreads work well with the RPM sensitive nature of small gas and diesel engines. For many years, these conventional transmissions were primarily three and four forward speed units and in automatic, of course, incorporated a neutral, park and reverse mode as well.

Over the last two decades the number of forward speeds has continued to increase in an attempt to squeeze more efficiency out of a less than efficient engine design. As the number of forward speeds has increased (now up to ten forward ratios), the size and weight has also increased, and here is the PAIN! Electric car conversions are very weight sensitive and space is always at a premium.

Retaining the conventional multi-speed transmission when converting to electric power is wasteful to the extreme.

Electric motors as a rule are much higher in efficiency and make their peak torque right from a stop and over a much broader rpm range. This means that many electric car conversions could do very well with a smaller, lighter transmission package. In fact, most could do well with a single forward speed reduction gear box (the ev - TorqueBox®). As an example, all Tesla vehicles use a single speed gearbox. This is of course true of most all new plug-in electric cars.

Also, brushless DC and all AC motor conversions do not need a reverse gear in the transmission as they can simply turn the motor in the reverse direction to back the vehicle up.

EV TORQUEBOX®

Standard TorqueBox® with Fixed Yoke and Optional ParkLock System

Standard TorqueBox® with Optional Cast or Billet Slip Yokes

TorqueBox® Extreme Duty Reduction Gearbox

Available Upon Request

"Torque Tough TorqueBox® Components from Torque Trends Inc. - Tail Housing Mounts, Yokes, and Parklock Sections."

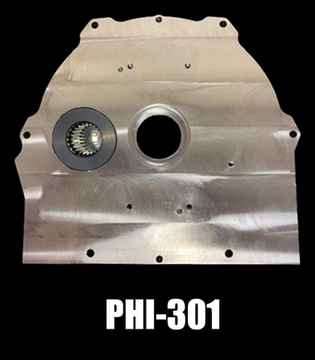

"Torquebox® Adapter Plates

to Fit Popular Electric Motors"

Adapter plates are used to join the electric motor and the TorqueTrends brand reduction gearbox. Either a custom input shaft is created for the EV transmission adapter, or we use our standard input shaft and a splined coupler to lock the motor's output shaft to the gearbox planetary gearset. Typically, a motor with an internally splined motor shaft gets a custom-built input in the EV TorqueBox® and a motor with an externally splined motor shaft gets our splined coupler and standard input shaft.